Overview and context

This guidance seeks to complement Policy MC6 of the Adopted Core Strategy 2011 by outlining the importance of safeguarding mineral resources and development from sterilisation and prejudice by other development.

Importance of minerals

Minerals provide the building blocks of United Kingdom (UK) society and are fundamental to its transition to a low-carbon, resilient, and resource-efficient economy. They are essential for a range of industries and technologies from construction to automotive, medical devices to renewable energy infrastructure. Surrey uses considerable amounts of minerals to sustain its economy, most of which are imported as finished products.

Surrey's minerals industry provides raw materials for the UK economy and local employment. Many jobs also rely indirectly on Surrey's minerals industry, such as those in construction and associated service industries. These make a significant contribution to the wealth and quality of life of Surrey's residents.

It is therefore vital that there is a steady and adequate supply of minerals in Surrey: aggregate minerals for building and repairing houses, roads, schools, and hospitals; non-aggregate minerals to serve industrial applications such as glass, paint, and ceramics manufacture; and energy minerals which play a crucial role in national security and the UK economy.

Surrey's minerals

Mineral resources are natural concentrations of minerals. In the case of aggregates, this may relate to bodies of rock that are, or may become, of potential economic interest due to their inherent properties. Details of existing minerals, their location, and uses can be found in factsheets published by the British Geological Survey.

For land-use planning purposes the term 'minerals' is defined in section 336 of the Town and County Planning Act 1990 (the 1990 Act) and includes all substances of a kind ordinarily worked for removal by underground or surface working, though this does not include peat cut for purposes other than sale.

Minerals are divided into two broad categories. Bulk minerals used in building and construction like rock, sand, and gravel, and all the other types of minerals such as silica sand, clay, and oil and gas. The range of mineral resources available in different parts of the Surrey reflect its underlying geology:

- Soft sand.

- Sharp sand and gravel.

- Silica sand.

- Brick clay.

- Building stone.

- Chalk.

- Fuller's earth.

- Oil and gas.

- Peat.

Production of sharp sand and gravel for concreting aggregate is concentrated in the Thames Valley and the lower reaches of the Wey Valley in northwest Surrey. Soft sand working for building purposes is restricted to a narrow outcrop of the Lower Greensand Formation which runs east-west across the centre of the county. Silica sand also occurs in the Lower Greensand Formation but is more restricted, occurring from east of Dorking to west of Godstone.

Brick Clay comprises the Wealden clays which outcrop extensively across the southern part of Surrey. Building stone, largely Bargate Stone, coincides with Surrey's Weald Clay Formation and extends in a broad west-east belt through the centre of the county.

Resources of oil and gas are confined to the Weald Basin and the southern parts of the county, but surface well sites can be located some distance from the target oil and/or gas reservoir rocks due to techniques such as directional drilling.

Chalk resources outcrop as part of the prominent escarpment of the North Downs in Surrey, whilst fuller's earth, a sedimentary clay, occurs in Lower Greensand exposures north of the A25 between Redhill and Godstone.

Small deposits of peat do exist in the county but there is no record of commercial peat extraction having been undertaken in the past. The areas of peatland encountered in Surrey are lowland areas of raised mires (domes of peat) or fens (sedge peats). These areas typically coincide with wet heathland and bog habitats.

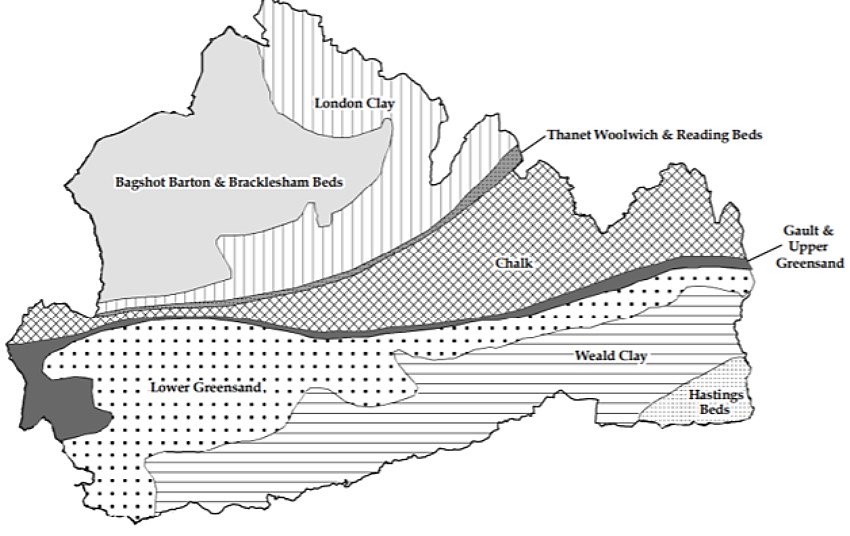

Figure 1. Geology of Surrey - this figure shows the Bagshot Barton and Bracklesham Beds, and London Clay to the north and north-west of Surrey, chalk in the east and Weald Clay and Hastings Beds in the south-east. The west of the county is comprised mainly of the Lower Greensand and the Gault and Upper Greensand.

Contemporary mineral production in Surrey is centred on aggregates for construction and civil engineering, brick clay for building, silica sand for industrial use, and oil and gas.

Sharp sand and gravel are currently produced in the Staines-upon-Thames, Shepperton and Laleham areas in the borough of Spelthorne, and preferred areas for future extraction have been identified in the boroughs of Spelthorne and Runnymede.

Soft sand is being extracted from Moorhouse Sandpits near Westerham on the Kent border, at Mercers South Quarry near Nutfield to the east of Redhill, and at Alton Road Sandpit to the west of Farnham. Silica sand is extracted at North Park Quarry and the associated Pendell Quarry to the east of Bletchingley and west of Oxted.

Brick clay is worked at South Holmwood Brickworks near Beare Green and at Ewhurst Brickworks near Walliswood in the south of the county.

Oil and gas are produced at several sites across the county from Albury in the west, through Brockham and Bletchingley in the centre, to Palmers Wood and Horse Hill in the east.

Mineral development

Section 96(6) of the Environment Act 1995 explains that the term 'mineral development' is any development primarily involving the extraction, processing, storage, transportation, and manufacture of minerals, and extends to include the act of depositing mineral waste. Consequently, important rail infrastructure used for the transport of minerals (including recycled and secondary aggregate) and facilities concerned with the manufacture of recycled and secondary aggregate are also forms of mineral development.

The terms 'mineral working' or 'mineral extraction' generally refer to the quarrying of minerals, and ancillary infrastructure such as processing plants, site offices, storage facilities, and weighbridges etc. Similarly, a 'mining operation' is the act of winning or working mineral in, on, or under land, whether by surface or underground working. 'Winning' a mineral means making the mineral available or accessible to be removed from land; whilst 'working' a mineral means to remove it from its position in or under land.

In a two-tier local authority area such as Surrey, the county council (SCC) is the Mineral Planning Authority (MPA) and responsible for the preparing local plans and determining planning applications relating to mineral development.

Although mineral development is a temporary use of land, it often takes place over a long period of time. This means that there may be the need for the MPA to carry out periodic reviews of conditions imposed on planning permissions to reflect modern standards and ensure that high standards of mineral working, and restoration are maintained.

Mineral infrastructure

Aggregate is sand, gravel or crushed rock used in the building and construction industries. Recycled aggregate is therefore sand, gravel or crushed rock originally used as a building material in some form, that has been recycled or otherwise processed for reuse. The main materials from which recycled aggregate is produced include construction, demolition and excavation waste and bituminous materials arising from road engineering works. Secondary aggregate (not to be confused with recycled aggregate) is derived from industrial by-products (such as incinerator bottom ash) and from mineral wastes.

Recycled and secondary aggregates can be used in construction activities as a replacement for primary materials such as land-won and marine aggregates (particularly sharp sand and gravel) thereby keeping materials in the economy as long as possible, reducing reliance on raw materials, and preventing waste.

Surrey benefits from a network of aggregate recycling facilities located throughout the county. Generally, temporary facilities coincide with aggregate quarries whilst permanent facilities are established as or form part of waste management facilities. Together these facilities produce about 1 million tonnes (mt) of recycled aggregate each year.

Rail aggregate depots facilitate the long-distance transportation of land-won and marine minerals (and in some cases recycled and secondary aggregate) which are then distributed locally by road. They also play an important role in providing minerals that do not occur in the Surrey or the region. In this regard they provide for the sustainable movement of substantial volumes of minerals across England, Southeast England, and Surrey thereby reducing dependence on road transport and associated traffic congestion and carbon and vehicle emissions. This is important in the context of air quality and climate change. Long-distance transportation of large volumes of minerals by rail is also more economic than by road.

Surrey benefits from two rail aggregate depots. One in Woking town centre, and the other at Salfords between Redhill and Horley. These depots present a good geographic spread between the west and east of the county, and their rail connections enable the supply of crushed rock from the West Country or crushed rock and marine sand and gravel from wharves on the Thames Estuary.

Surrey imports over 1 mt of rail-borne aggregates each year, either directly or via surrounding rail depots. Of the total amount of aggregate imported into Surrey from surrounding rail depots, Crawley, Purley and Tolworth each contribute approximately one-third of total imports.

Mineral safeguarding

Minerals can only be worked where they are found, but some resources have previously been worked, are sterilised, or cannot be worked due to the presence of other development or sensitive environmental designations. For these reasons and given their importance to UK society and its economy, safeguarding mineral resources, sites, and infrastructure is an important part of land-use planning in England.

Mineral safeguarding is partly achieved by identifying Mineral Safeguarding Areas (MSAs) and areas of search as part of the Minerals Development Framework (MDF). The purpose of an MSA is to define an area where potentially viable mineral resources are likely to be present and to safeguard them from direct sterilisation by other development. Areas of search generally coincide with MSAs, and although they reflect an absence of detailed knowledge about potential mineral resources, they do enable industry to plan for the longer term should those resources become commercially viable. They also help make other stakeholders, including residents, aware that mineral development may take place in a particular area.

Mineral safeguarding is also achieved by:

- Using best available information about the location of all mineral resources.

- Consulting stakeholders (including the minerals industry) when defining MSAs.

- Providing information about MSAs on the policies map related to the MDF.

- Providing for clear development management policies and guidance which set out how proposals for non-minerals development in MSAs will be managed, and what action developers should take to address the risk of prejudicing mineral resources, sites, and infrastructure.

Surrey's eleven Local Planning Authorities (LPA) are responsible for determining most planning applications, and preparing local plans to meet longer term needs of residents such as housing. It is therefore important that LPAs work with the MPA to ensure that new development does not prejudice land safeguarded to protect mineral resources.

In addition to its role as MPA, SCC is also responsible for development undertaken pursuant to Regulation 3 and 4 of The Town and Country Planning General Regulations 1992. This type of development is commonly referred to as 'county council development' and involves SCC's own development such as schools, transport infrastructure, libraries, care homes, fire stations etc. Consequently, SCC should also cooperate with the MPA to ensure that their development does not prejudice land safeguarded to protect mineral resources.

As well as safeguarding mineral resources, the MPA also seeks to safeguard the effective operation of existing mineral sites and infrastructure. This is necessary to support the minerals industry in providing for a steady and adequate supply of minerals and preserve land for future working. Of particular importance in this regard are rail aggregate depots and aggregate recycling facilities.

Given their industrial nature and scale, the operation of existing mineral sites and infrastructure can give rise to impacts and emissions which may have an adverse impact on local amenity. Such impacts could include increased traffic and congestion, vehicle emissions, noise, and dust. Consequently, development in the vicinity of existing mineral sites or infrastructure and which are sensitive to such impacts (such as houses and offices) may prejudice their continued or effective operation which could in turn lead to indirect sterilisation of viable mineral resources.

The following land in Surrey is safeguarded for mineral development:

- Sites and associated facilities in mineral use.

- Sites with planning permission for mineral development.

- Preferred areas for future mineral development.

- Areas of search identified for possible mineral development.

- Land likely to contain economically viable mineral resources.

- Rail aggregate depots.

- Sites being used for production of recycled or secondary aggregate.

- Sites with planning permission for production of recycled or secondary aggregate.

Planning policy

The National Planning Policy Framework 2024 (NPPF) explains, at paragraph 7, that the purpose of the planning system is to contribute to the achievement of sustainable development and that this means meeting the needs of the present without compromising the ability of future generations to meet their own needs. It goes on to elaborate, at paragraph 8, that achieving sustainable development means meeting three objectives:

- To help build a strong, responsive, and competitive economy by ensuring that sufficient land of the right type is available in the right places and at the right time to support growth, innovation, and improved productivity; and by identifying and coordinating the provision of infrastructure.

- To support strong, vibrant, and health communities by ensuring that a sufficient number and range of homes can be provided to meet the needs of present and future generations.

- To protect and enhance our natural, built, and historic environment, including making effective use of land, using natural resources prudently, minimising waste and pollution, mitigating and adapting to climate change, and moving to a low carbon economy.

Chapter 17 of the NPPF is concerned with facilitating the sustainable use of minerals, and paragraph 222 explains that it is essential that there is a sufficient supply of minerals to provide the infrastructure, buildings, energy, and goods that the country needs. Since minerals are a finite natural resource, and can only be worked where they are found, best use needs to be made of them to secure their long-term conservation.

In this context the NPPF goes on to advocate, at paragraph 224, that when determining planning applications great weight should be given to the benefits of mineral extraction, including to the economy.

Paragraph 225 of the NPPF is clear that LPAs should not normally permit other development proposals in an MSA if it might constrain potential future use for mineral working; and paragraph 223 encourages the MPA to safeguard minerals so that important minerals remain available for use.

Annex 2: Glossary of the NPPF defines minerals of local and national importance. It says that these include aggregates, brick clay, oil and gas, and local minerals of importance to heritage assets of local distinctiveness (for example Bargate stone for Listed Buildings).

The principles established by paragraphs 222 and 223 are consistent with paragraph 200 of the NPPF which sets out that planning policies and decisions should ensure that new development can be integrated effectively with existing businesses and facilities (including mineral sites and infrastructure); and that these should not have unreasonable restrictions placed on them because of development permitted after they were established. Where the operation of an existing business or facility (including mineral sites and infrastructure) could have a significant adverse effect on new development (including changes of use) in its vicinity, the applicant (or 'agent of change') should be required to provide suitable mitigation before the development has been completed.

Policy MC6 (Safeguarding mineral resources and development) of the Surrey Minerals Plan Core Strategy 2011 (SMPCS) sets out that MSAs have been defined for resources of concreting aggregate, soft sand, silica sand, brick clay and fuller's earth, and that the MPA will seek to prevent sterilisation of these resources by other development. It also explains that infrastructure and sites used, or proposed to be used, for mineral development including rail aggregate depots and sites for production of recycled and secondary aggregate will also be safeguarded.

In respect of resource efficiency, Policy MC4 (Efficient use of mineral resources) promotes the use of sustainable design and construction that provides for efficient use of minerals and enables the incorporation of a proportion of recycled or secondary aggregate in new development. It explains that borrow pits associated with major development will be supported subject to the mineral resource being close to the development site, use of that mineral being used specifically for that development, and restoration of the pit being tied to the completion of the development.

The SMPCS forms part of the Development Plan for Surrey. For this reason, Section 70(2) of the 1990 Act, Section 38(6) of the Planning and Compulsory Purchase Act 2004, and Section 92(5) of the Levelling Up and Regeneration Act 2023 stipulate that planning applications should be determined in accordance with Policies MC4 and MC6 unless material considerations (strongly) indicate otherwise.

Planning consultations

Policy MC6 of the SMPCS explains that LPAs will be expected to consult the MPA about any proposals for development that would:

- Prejudice the effective operation of existing and future mineral sites.

- Sterilise mineral resources in preferred areas for future mineral extraction.

- Sterilise mineral resources within MSAs.

Preferred areas for the supply of sharp sand and gravel and soft sand are provided for by Policy MC7 of the SMPCS and identified by Policies MA2 and MA3 of the Surrey Primary Aggregates Development Plan Document 2011 (PADPD).

Preferred areas and areas of search for the supply of silica sand are provided for and identified by Policy MC8 of the SMPCS. Proposals for brick clay extraction within areas of search are provided for and identified by Policy MC9 of the SMPCS.

The location and extent of existing mineral development in the county including MSAs, preferred areas, and areas of search for mineral extraction can be seen in the MPA's interactive policy map on Surrey County Council's website.

MSAs are treated as Mineral Consultation Areas (MCA) for the purposes of the SMPCS meaning that proposals for development which may affect these areas should be the subject of consultation with the MPA. In the case of existing and proposed sites for mineral development, consultation about development within 200 metres of a site boundary should be provided for by LPAs.

In considering any development proposal, a realistic judgement about the likelihood of mineral being worked in an environmentally acceptable way will be made, and the MPA will not seek to prevent development where it is unlikely that extraction of the mineral would occur in the future.

Where mineral deposits are believed to exist, but detailed geological information is not available, the existence or otherwise of a potentially workable resource may need to be established by the developer, by undertaking a Mineral Resource Assessment (MRA) before any application for development that might sterilise the potential deposit is determined.

In the interests of resource efficiency, the MPA will treat prior extraction of mineral resources as an important objective when consulted about development within a MSA and which would otherwise result in sterilisation of that resource.

In some circumstances the complete or partial prior extraction of mineral resources underlying an application site may enable a development to proceed without a safeguarding objection from the MPA. Even in circumstances where significant prior extraction is not practicable or viable there may still be scope for incidental extraction where the mineral is processed and used on the application site to facilitate the development.

It is for the developer to demonstrate whether prior extraction is viable. A MRA may conclude that prior extraction is not practicable due to one or more factors including physical constraints, proximity to sensitive receptors, unacceptable delay to a construction timetable, or the impact of extraction on landform making the proposed development unviable. The MPA will consider the conclusions of any MRA, including feasibility of prior extraction, in forming its view about the proposed development in the context of mineral safeguarding.

Resource assessment

The economic viability of mineral resources and their extraction may change over time as resource becomes scarcer and markets and economic circumstances change. It is important therefore that MRAs are submitted alongside planning applications even in situations where the principle of development in a MSA has be previously established by way of allocation in a local development plan.

The scope and level of detail in any MRA will depend on the nature and scale of the proposed development and other circumstances including the location of the application site. In preparing an MRA the following matters should be considered:

- Nature, scale, and location of the development proposed.

- Estimation of the quality and quantity of mineral resource which may be impacted by the proposed development verified by evidence from bore hole investigations where appropriate.

- Assessment of whether the proposed development could be modified to avoid sterilisation.

- Assessment of the potential for use of the mineral resource in the proposed development and whether it would be feasible to extract the mineral resource in advance of the development.

- Assessment of the commercial and practical considerations of prior extraction including environmental and amenity impacts, the location of processing facilities, methods of transport, and commercial interest of the mineral industry.

- Where prior working is feasible and practicable, an explanation of how this is to take place including its impact on the deliverability and viability of the proposed development.

Infrastructure assessment

Proposals for development within 200 metres existing mineral sites including aggregate recycling facilities and rail aggregate depots should be supported by a Minerals Infrastructure Assessment (MIA).

A MIA should provide sufficient information and evidence to enable the MPA to assess whether the proposed development is likely to be prejudicial to the continued operation or capacity of the existing mineral site.

Where development would be sensitive to impacts arising from an operational mineral site, a MIA should include sufficient information to demonstrate that its design includes appropriate measures to mitigate such impacts to acceptable levels. Such measures could include hard and soft landscaping, orientation of buildings, layout of application site including vehicular access(es), additional or enhanced noise insultation etc.

Pre-application engagement with the MPA and mineral operators is encouraged to ensure that any potential mineral safeguarding issues are properly identified and considered at the earliest possible stage.